WE MAKE DESIGN AND ORDERING EASIER

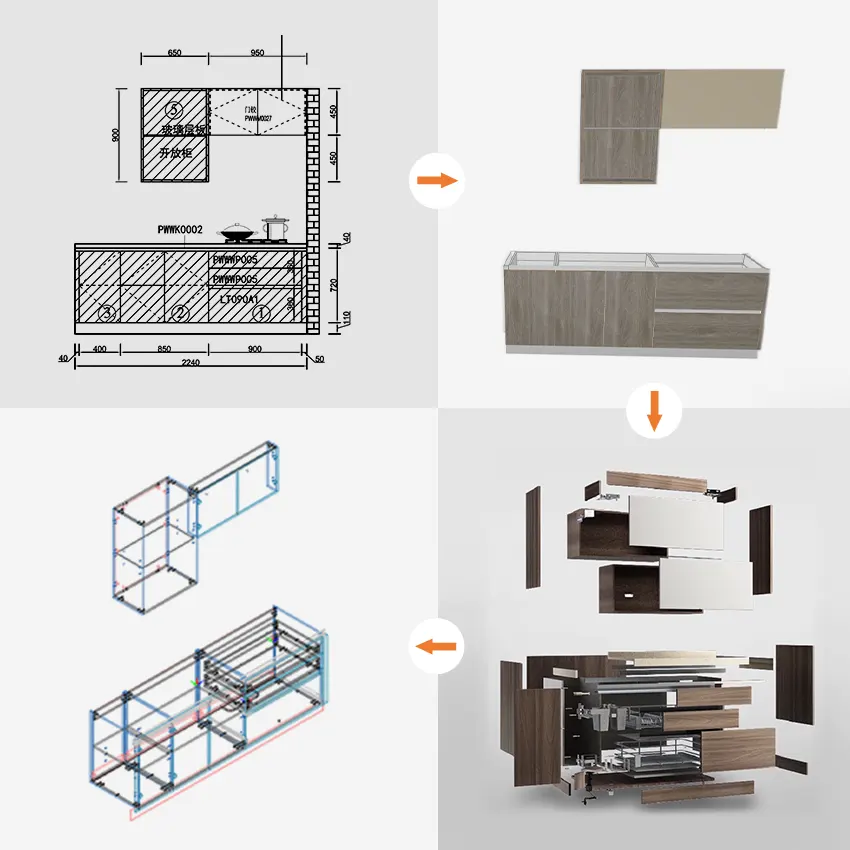

- Oppein utilizes an ultra-efficient designer tool – CAXA, which can make a 3D model from the original design script within 1 hour and provide a quotation list in only 3 minutes. .

- With the CRM system integration, we could identify each order and track the order stage to the second. Never worry about order delays, as we make it to a very specific point.

WE PROMISE ACCURACY IN PRODUCT DIMENSIONS

- After your order has been confirmed and your designs have been prepared, a cabinet-splitting system allows you to view the dimensions and details of each panel in greater detail.

- From 3D rendering to cabinet configuration, then to a components list, we make every stage visible and efficient, ensuring 0 mistakes in actual production

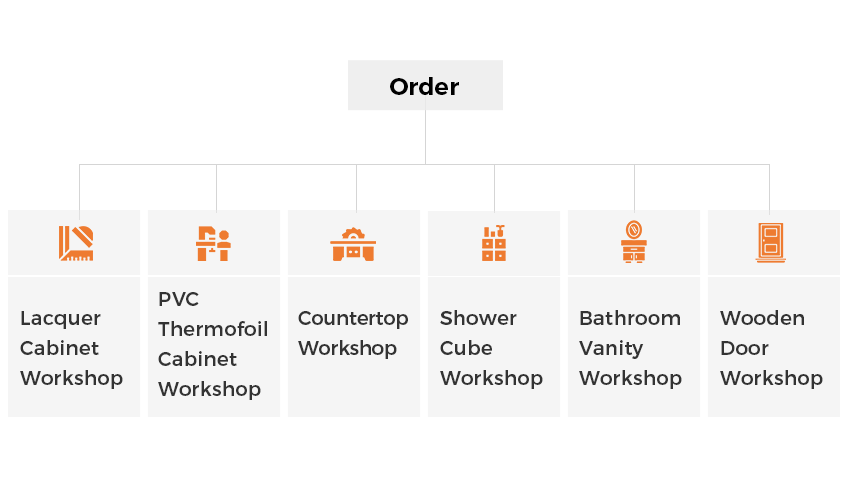

WE PROVIDE EFFICIENT MANUFACTURERING OUTPUT

- Oppein cabinet factory operates over 96 workshops for manufacturing specific product parts, including lacquer cabinet workshops, countertop workshops, wooden door workshops...

- Our intelligent order management system ensures the production schedule after arranging specific workshops for manufacturing. That's how we estimate the exact lead time for each order.

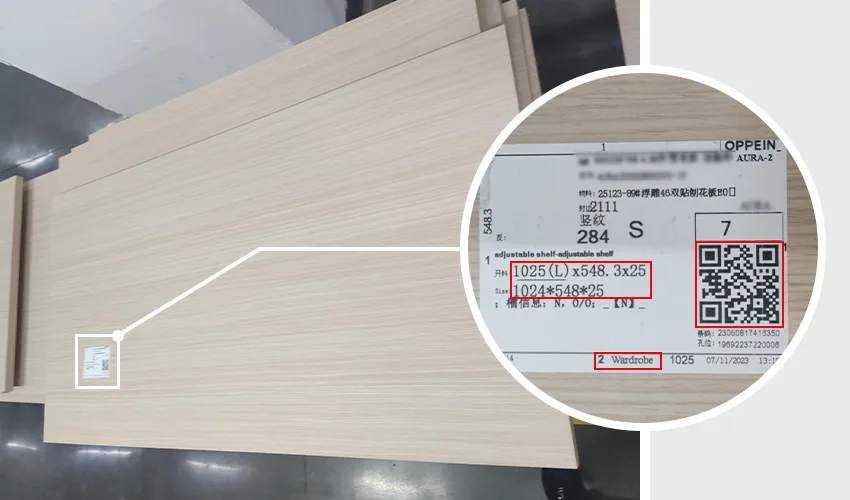

WE GUARANTTEE THE EXACT QUANTITY OF PRODUCTS

-The cabinet factory labels all parts of the cabinet, such as the door panel, carcass, and so on, to verify the exact production quantity.

- With unique labels on product parts, the order identification system can scan automatically to identify the exact quantity for each order. You have no worries about missing production items.

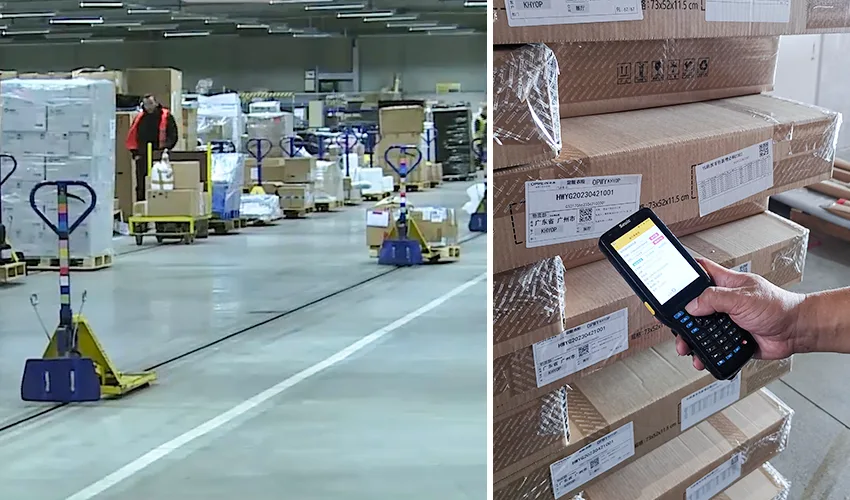

WE AVOID MISS-PACKING OR LOADING

- Intelligent cabinet factory management ensures an automated logistic system between factories and warehouses for the transportation of products, thereby ensuring that no items are left in the factory after production.

-Double confirmation: Before warehousing, we scan the products for the correct number of items to be stored, and before loading, we scan the package to ensure that no products have been missed.